Surface treatments for metal

Reading Time: 5 min.

Learn what distinguishes metal surface treatments, what processes are available and how they are used in practice.

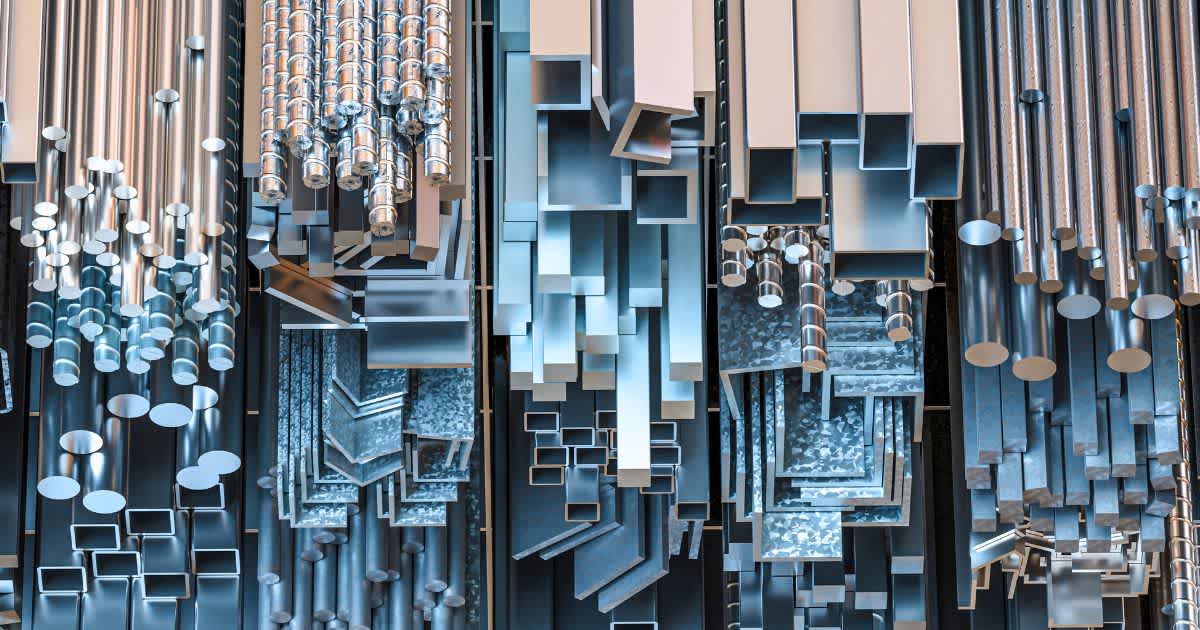

Whether in sheet metal working, mechanical engineering, automotive production or consumer goods manufacturing – without metals, it would be almost impossible to manufacture modern products. However, raw metal alone rarely meets the high requirements for durability, appearance and functionality. This is where surface technology comes into play: it refines metals, protects them from corrosion and gives them the desired properties.

What is meant by surface treatment of metals?

Surface treatments are processes used to specifically modify or refine the outer layer of a metal component. The aim is not only to achieve an attractive appearance, but above all to provide protection and functionality. This is because untreated metal is susceptible to corrosion, wear and dirt. Professional surface treatment, on the other hand, extends service life, improves quality and ensures reliable product properties.

The processes are as varied as their applications: mechanical treatments such as grinding or polishing ensure smooth surfaces, while chemical processes such as passivation or pickling protect the metal against environmental influences. Coatings, galvanic processes or special techniques such as anodising open up further possibilities for adapting components precisely to their conditions of use.

It is important for buyers and procurers to not only be familiar with surface technology, but also to understand the manufacturing process itself. You can read more about this in the article: Modern manufacturing processes for metal.

4 reasons why metals are treated

Quality assurance

Products only reliably meet specific standards such as DIN, ISO 9001 or CE marking if the surfaces have been treated accordingly.

Cost-effectiveness

An extended service life reduces failures, rework and complaints.

Appearance and market value

High-quality metal finishing contributes to the appearance and thus also to the value of the end product.

Specific properties

Conductivity, friction values or resistance can be specifically adjusted by means of the appropriate surface treatment.

This is crucial for the logistics and procurement industry: surface treatments not only influence product quality, but also supply chains, costs and certification processes.

Overview of surface treatment processes

Mechanical processes

Mechanical processes treat the surface directly through physical action. They are among the oldest methods of metalworking and offer the advantage of being flexible in their application to different metals and component sizes.

Grinding: Removes unevenness and creates a uniform structure. Particularly important for components that will later be coated or painted.

Polishing: Creates mirror-smooth surfaces and ensures aesthetically high-quality finishes, for example in consumer goods or decorative elements.

Blasting: Sand, glass or shot blasting is used to clean, roughen or harden the surface. This effectively removes dirt, rust and old coatings.

Chemical processes

Chemical surface treatments rely on reactions with liquids or gases to alter the properties of the material. As they ensure consistent and reproducible quality, they are widely used in series production.

Pickling: Removes oxide layers and impurities from the surface, preparing the metal for further steps. Passivation: Forms a protective layer that protects the metal from corrosion – particularly common with stainless steel.

Phosphating: Creates a conversion layer-like base that provides corrosion protection and serves as an adhesive primer for paintwork.

Chromating: A versatile method that combines corrosion protection and electrical conductivity.

Electroplating processes

Electroplating involves coating metals with a thin layer of another metal using electrochemical processes. Electroplating processes are a core area of metal finishing and ensure a close connection between functionality and design.

Zinc plating: Particularly common for protecting steel from corrosion.

Nickel plating: Creates a hard, wear-resistant surface that is also visually appealing.

Chrome plating: Provides shine, hardness and durability – often used in the automotive industry.

Coatings (coating processes)

Coatings apply an additional layer to the metal surface, usually by painting, powder coating or plastic coating. Coating processes are versatile and can be used in both large-scale production and customised solutions.

Painting: Classic process for combining colour, protection and appearance.

Powder coating: Environmentally friendly, as it does not use solvents, and highly resistant to mechanical stress.

Plastic coatings: Make metals resistant to chemicals or moisture.

Special processes

In addition to traditional methods, surface technology is constantly developing new processes. The following developments show that surface treatments are not only a traditional form of protection, but also a driver of innovation.

Anodising: Particularly suitable for aluminium, anodising produces a hard, corrosion-resistant oxide layer that can also be coloured.

PVD coating (physical vapour deposition): Thin layers with high hardness and wear resistance, often used in the tool industry.

Nanocoatings and plasma processes: Increasingly relevant in high-tech industries, as they enable extreme durability with minimal use of materials.

Practical application examples

Surface treatments play a crucial role in sheet metal processing – for example, in pickling, phosphating or powder coating to ensure corrosion protection and paintability. They create the basis for sheet metal to remain durable and resistant in construction, housing manufacturing or vehicle construction.

In mechanical engineering, hardening, nickel plating or functional coatings ensure that heavily stressed components such as gear wheels or bearing surfaces remain wear-resistant. This reduces failures and extends maintenance intervals.

The automotive industry combines protection and design. Galvanic processes such as chrome plating or anodising are used for both visible trim parts and safety-relevant components.

Polished or coated surfaces also play a central role in consumer goods manufacturing. High gloss, colour variety and scratch resistance increase the perceived value and thus the purchasing decision of end customers.

For procurers and purchasers, the choice of the appropriate process depends on function, quantity, standards and costs. A targeted comparison is worthwhile in order to ensure both quality and cost-effectiveness.

Surface technology in procurement: what purchasing departments should look out for

In international procurement, the right surface treatment often determines the success of a project. The following aspects are key:

Quality certification Standards such as ISO 9001 or CE marking provide assurance that processes are standardised and controlled.

Supplier selection Not every manufacturer is proficient in all processes. A reliable partner must have proven experience with the required standards.

Sustainability Environmentally friendly coating processes, solvent-free coatings and resource-saving processes are becoming increasingly important.

Costs and cost-effectiveness High-quality surface treatment may incur higher acquisition costs, but reduces overall costs in the long term through fewer failures and complaints.

High-quality surface treatment also depends on the choice of manufacturing process. Read more about this in our article CNC vs. injection moulding – choosing the right process.

Conclusion: Surface treatment is essential

Surface treatments are much more than just a cosmetic measure. They ensure the quality of components, extend their service life and create competitive advantages in global supply chains.

They are a key criterion for the logistics and procurement industry: only those who know the processes and demand the appropriate standards can have their products manufactured economically and reliably.

Line Up supports you in this – from selecting the right coating process to quality control in international production facilities. With our experience, global network and clear processes, we ensure that your metals have exactly the properties you need.

Do you have questions about the right surface treatment or need support with your project?

Make an appointment now using our contact form – we will advise you personally and individually.

Newsletter Registration

Sign up now for our free Line Up newsletter and stay up to date.