Table of Contents

- What is series production?

- Custom manufacturing, series production, mass production: An overview of the most important types of manufacturing

- Advantages of series production

- Challenges and limitations of series production

- Series production in practice: examples from industry

- Small series, medium series, large series: differences explained

- Series production in the digital age

- Professional series production with Line Up

- Frequently asked questions about series production

- Conclusion: When is series production the right choice?

Series production: How to get started

Reading Time: 6 min.

A product has been fully developed. The prototype is convincing. Demand is growing. But how do you reliably put a concept into production, not just once, but hundreds or thousands of times?

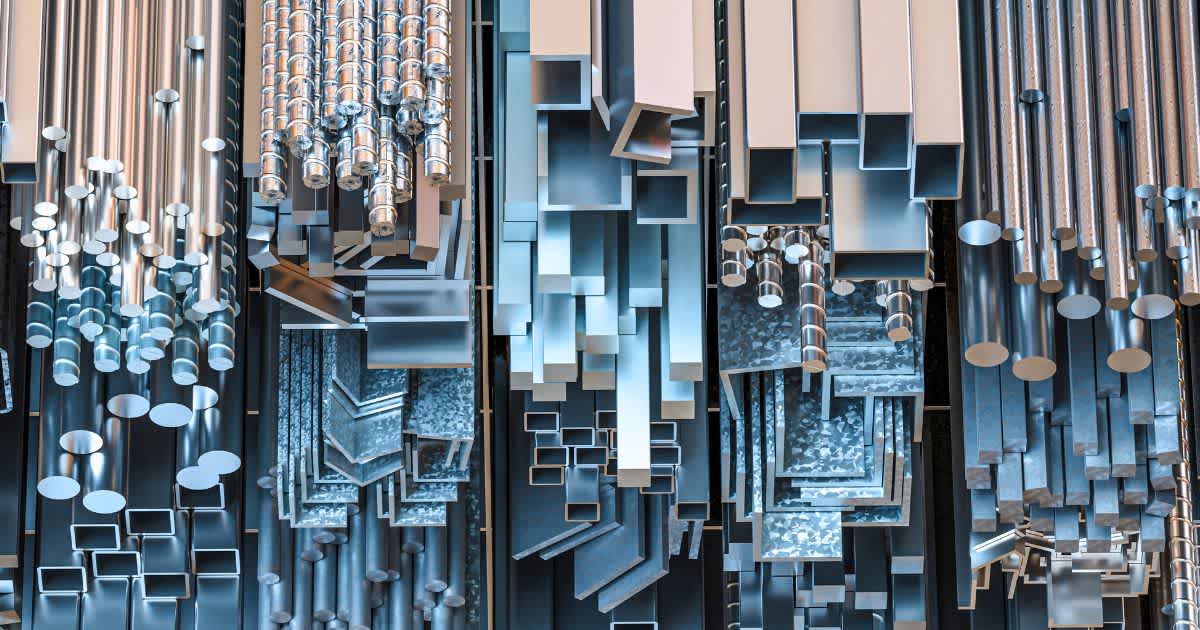

This is where series production comes into play. It is the link between the idea and industrial scale. Whether complex machine components, tools, or clothing, series production makes it possible to manufacture products with consistent quality and predictable costs.

Series production has become an integral part of modern industry. But what exactly does the term series production mean, what types of manufacturing are there, and when is series production the right choice for your company?

This article provides a comprehensive overview of series production, from its definition and advantages to challenges and practical examples from industry.

What is series production?

Series production describes a form of production in which similar products are repeatedly manufactured in limited quantities. In contrast to single-item production, a product is not manufactured just once, but is produced in a series with identical or very similar characteristics.

The term series manufacturing is also frequently used. Both terms are used synonymously and refer to the same type of production. The aim of series production is to establish standardized processes in order to reduce costs, ensure quality, and shorten production times.

In the context of production types, series production occupies a middle position. It is more flexible than mass production and at the same time more efficient than single-item production. It is precisely this balance that makes it particularly attractive for many companies.

Custom manufacturing, series production, mass production: An overview of the most important types of manufacturing

To properly classify series production, it is worth taking a look at the main types of manufacturing in industry.

Single-item production

Single-item production is characterized by the fact that each product is manufactured individually. Typical examples are special-purpose machines, prototypes, or customer-specific systems. The advantage lies in the high degree of flexibility, but the unit costs are usually very high.

Series production

Series production or serial production relies on the repeated manufacture of similar products in fixed series. Adjustments can be made between individual series. This type of production offers a good compromise between efficiency and adaptability.

Mass production

Mass production, on the other hand, aims to produce very large quantities of an identical product. The processes are highly automated and changes can only be made at great expense. Typical areas of application are consumer goods or standardized components.

A comparison of the different types of production shows that series production is particularly suitable for companies that regularly manufacture similar products but still need to respond to market requirements.

Advantages of series production

Series production offers numerous advantages, making it one of the most widely used types of production in industry.

Cost efficiency: Repetitive processes allow material usage, setup times, and work processes to be optimized. Fixed costs are spread over larger quantities, which reduces unit costs.

Higher productivity: Well-established processes and specialized machines enable shorter throughput times and higher utilization of production capacities.

Stable quality: Standardized processes improve process reliability. Sources of error are identified at an early stage, which facilitates quality control.

Predictability: Series production allows for precise planning of production quantities, delivery times, and resource utilization, which is crucial for supply chains and customer relationships.

Challenges and limitations of series production

Despite its advantages, series production also presents challenges that companies should take into account.

One key issue is setup costs. Switching between different series requires changes to machines, tools, or processes. These times must be factored into the economic planning.

In addition, flexibility is limited compared to individual production. Individual customer requests can only be implemented to a limited extent without disrupting the production process.

Planning also plays a crucial role. Incorrect demand forecasts can lead to overproduction or delivery bottlenecks. Precise sales planning is essential, especially for larger series or mass production.

Finally, as series sizes increase, so do the demands on logistics, warehousing, and quality management.

Series production in practice: examples from industry

In industrial practice, series production is used in numerous sectors. Examples include:

Mechanical engineering

In mechanical engineering, complex assemblies are often produced in series. These require precise coordination, reliable quality, and a high degree of technical documentation. Series production enables cost-effective implementation while maintaining technical flexibility.

Construction industry

The construction industry requires precisely fitting components that must be delivered reliably and in consistent quality. Mass-produced products such as fasteners, profiles, or special components ensure predictable execution on the construction site.

Tools and accessories

For tool manufacturers, mass production offers the opportunity to implement complete product lines in consistent quality. From hand tools to special attachments, series are created that are precisely tailored to their function and area of application.

Sanitary products

In the wholesale trade for sanitary products in particular, series production is essential for implementing own brands with consistent quality and individual designs. Packaging concepts and logistics processes are also used here as part of the series solution.

Tip: At Line Up, we support projects with a wide variety of requirements and products—from functional components to design-oriented consumer goods. Learn more about our services here.

Small series, medium series, large series: differences explained

In series production, a distinction is often made between different series sizes. The appropriate series size depends on the product, market, and corporate strategy.

Small series

Small quantities, e.g., 10 - 100 units

High adaptability

Suitable for market testing or niche products

Medium series

100 - 1,000 units

Good combination of flexibility and efficiency

Ideal for medium-sized series manufacturers

Large series

More than 1,000 identical products

Highly standardized processes

Transition to mass production possible

Series production in the digital age

Digitalization is also bringing about lasting change in series production. Automation, Industry 4.0, and networked systems are playing an increasingly important role.

Modern production facilities enable flexible control of series sizes and variants. Digital production planning helps companies optimize processes and identify bottlenecks at an early stage.

Series tracking is also becoming increasingly important. Digital systems allow serial numbers, batches, and quality data to be documented seamlessly. This is a decisive advantage, especially in regulated industries.

Professional series production with Line Up

A good idea alone is not enough to successfully bring a product into series production. What is crucial is a partner who speaks the language of technology, understands processes, and can reliably manage international production processes.

At Line Up, we accompany global series production from the first testable sample to stable production in certified partner plants. Every project begins with a clear plan, a shared understanding of quality, and the goal of turning a concept into a market-ready series product.

For companies that don't want to leave their series production to chance, this offers a collaboration that not only delivers results, but also clarity, speed, and security throughout the entire process.

Frequently asked questions about series production

What is the difference between series production and mass production?

Series production involves manufacturing limited quantities of similar products, while mass production is designed for very large quantities of identical products.

When does series production become large-scale production?

Large-scale production starts at several thousand units. The processes are largely automated and highly standardized.

What are the advantages of series production for companies?

The most important advantages include lower unit costs, high productivity, better predictability, and consistent quality.

What are the typical challenges in series production?

Challenges include setup costs, limited flexibility, and high planning costs.

Conclusion: When is series production the right choice?

The initial idea. The functioning prototype. The step into industrial manufacturing. Anyone who wants to successfully follow this path needs a manufacturing solution that combines quality, efficiency, and scalability. Series production is precisely this key. It enables reliable workflows, economical processes, and consistently high quality.

Especially in times of increasing market demands, it is crucial to produce flexibly yet efficiently. Series production achieves precisely this balancing act, both in small series for special solutions and in large series for the international market.

Request products for series production now

Would you like to take the next step and put your product into series production? Our free dashboard makes it easy to submit product inquiries, transfer technical data, and monitor the entire process digitally.

Newsletter Registration

Sign up now for our free Line Up newsletter and stay up to date.