Table of Contents

- Modern sheet metal processing: methods, materials and digitalisation

- 5 Methods of modern sheet metal processing

- Materials in sheet metal processing

- Sheet metal processing 4.0: How digitalisation is changing processes

- Where sheet metal processing is heading

- What modern sheet metal processing has to achieve today

Guide: Modern sheet metal processing

Reading Time: 5 min.

Modern sheet metal processing: methods, materials and digitalisation

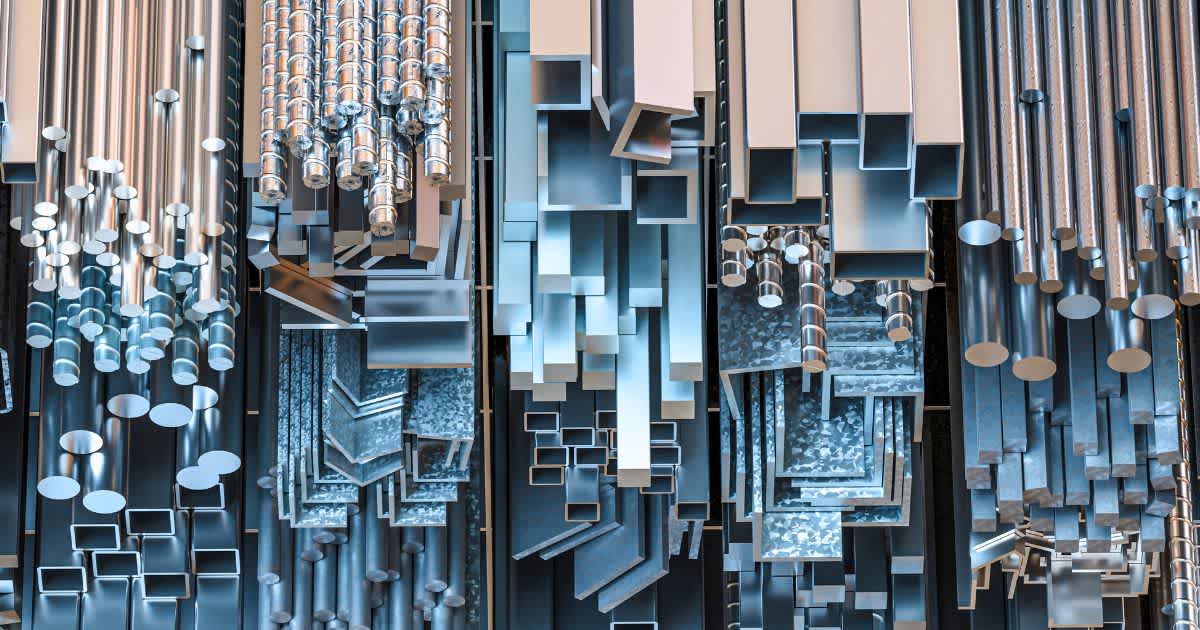

Barely any other material is as versatile as sheet metal. Find out which methods of sheet metal processing are used today and how you can make targeted use of digitalisation and automation for your projects.

Whether in mechanical engineering, electrical engineering, vehicle construction or the consumer goods industry - sheet metal is the material of choice wherever precisely manufactured, dimensionally stable and durable components are required. However, the demands on quality, speed and flexibility are increasing. At the same time, digitalisation, automation and new manufacturing technologies are changing the way sheet metal parts are produced.

5 Methods of modern sheet metal processing

The classic machining process in sheet metal production usually follows a linear sequence. Depending on the requirements, different processes and machines are used.

1. designing and programming

It all starts with the digital model. Components are geometrically designed using modern CAD systems and prepared for subsequent machining using CAM software. This phase already determines whether a part can be produced economically or whether it will lead to unnecessary rejects later on. Digitalisation enables seamless transitions between design, simulation and production control.

2. cutting

Material, thickness and geometry determine the appropriate cutting process and therefore have a significant influence on quality and cost-effectiveness. In practice, the following processes are primarily used:

Laser cutting: Particularly precise, even with complex contours and intricate cut-outs. Ideal for medium to large series and different materials.

Plasma cutting: Fast and powerful for thicker sheets, but with a lower edge quality.

Waterjet cutting: Suitable for heat-sensitive materials, as no thermal stresses occur. However, processing is more time-consuming.

3. forming

After cutting to size, the sheets are formed into the desired shape by pressing, bending or deep drawing. Depending on the complexity and component geometry, sheet metal forming tools such as conventional presses, CNC folding machines or automated bending cells are used. For maximum precision, modern forming processes are often monitored by sensors that record parameters such as bending angle, springback or force curves and adjust them in real time.

4. joining

The processed sheet metal parts must now be joined - either by screwing, riveting, gluing or welding. The latter is becoming increasingly precise thanks to automated processes. Robot-assisted welding in particular enables high repeat accuracy with short cycle times. Hybrid joining processes, such as bonding in combination with riveting, are also on the rise.

5. Surface treatment

The final surface treatment is crucial for function, durability and appearance - especially for safety-relevant or visible components. Different processes are used depending on the requirements.

Powder coating creates resistant corrosion protection with a uniform, coloured surface. Painting is particularly suitable for aesthetically demanding parts or components that are exposed to particular weather conditions. Stainless steel parts are often pickled and passivated to remove oxide layers and specifically increase corrosion resistance.

Materials in sheet metal processing

Depending on the area of application, sheet metal is processed in various thicknesses, surface qualities and alloys. The choice of material influences the entire production process. Close coordination between design, purchasing and production is therefore essential.

Steel

Robust, versatile and cost-effective. The materials used include structural steel, hot-dip galvanised steel and high-strength grades.

Stainless steel

Corrosion-resistant, durable and hygienic: particularly suitable for applications in the food, medical and chemical industries.

Aluminium

Lightweight, easy to form and rustproof: Ideal for lightweight construction, for example in automotive or aircraft construction.

Copper and brass

High electrical conductivity, good heat transfer and decorative properties: These materials are used for technical components, fittings and heat exchangers, among other things.

Sheet metal processing 4.0: How digitalisation is changing processes

The fourth industrial revolution - known as Industry 4.0 - is also fundamentally changing sheet metal production. Where there used to be individual machines, there are now networked systems that communicate autonomously, adapt themselves and control entire process chains.

Automation in practice

Automation has long been an integral part of modern sheet metal processing. Robots take over a variety of tasks that were previously carried out manually. In series production, for example, welding robots are used that guarantee consistently high quality and can work around the clock. The loading and unloading of presses is also increasingly automated using so-called handling systems, which position components safely and accelerate the material flow.

Combined production cells are a further step towards efficiency. They integrate several process steps - such as laser cutting, bending and assembly - into one automated unit. This allows throughput times to be shortened, set-up processes to be reduced and resources to be utilised in a more targeted manner. The result: greater reproducibility, better product quality and significantly fewer rejects, while at the same time reducing the workload on specialised personnel.

Sensors and IoT for machines that think for themselves

Sensors play a central role in networked sheet metal processing. They continuously measure parameters such as press force, temperature, vibrations or the condition of the tools. This data is transmitted to control systems or cloud platforms in real time and analysed. This enables a new quality of process control that is fast, precise and predictive.

Predictive maintenance is a key advantage: instead of adhering to fixed maintenance intervals, the system recognises wear or deviations at an early stage and initiates targeted measures before a failure occurs. At the same time, processes can be dynamically optimised as even the smallest deviations are automatically detected and corrected.

In addition, digital traceability increases transparency in production - every batch can be fully documented and analysed if necessary. This increases quality assurance and simplifies the obligation to provide evidence to customers and testing organisations.

Digital twins: simulation instead of trial and error

Digital twins are among the most important innovations in modern sheet metal processing, especially in the context of Industry 4.0. This creates a virtual image of real production, which can be used to simulate and optimise components, tools or entire process sequences in advance. This saves time, lowers development costs and reduces material waste.

The digital twin offers clear advantages, especially for complex components with tight tolerances. It makes potential sources of error visible at an early stage, allows precise adjustments to be made and improves the ability to plan production. In an environment dominated by variant diversity and short development cycles, virtual simulation is an effective tool for increasing efficiency and quality.

Where sheet metal processing is heading

The demands on sheet metal fabricators are increasing. Shorter delivery times, a greater range of variants and consistently high quality are required in the face of cost pressure and increasing demands for sustainability. Sheet metal processing is constantly evolving to meet these demands. New technologies are making processes more efficient, more intelligent and more environmentally friendly. Sustainable sheet metal processing is networked, flexible, data-based and resource-saving. The most important developments include:

Increasing levels of automation, even for smaller series sizes, thanks to collaborative robots and AI-based process controls

Adaptive manufacturing systems that adjust independently to new workpieces

Integrated production networks in which data from purchasing, design and production is available throughout

Sustainability through energy-efficient machines, material recovery and low-CO₂ processes

What modern sheet metal processing has to achieve today

Whether it's a single part or series production - anyone who wants to produce or procure sheet metal parts today needs more than just good material and proven machines. The ability to intelligently network sheet metal working processes, strategically utilise data and actively integrate technological innovations is crucial.

From design and the selection of suitable manufacturing companies to quality control and digital supply chain management, Line Up supports you as a strategic partner. With our international network and our digital supply chain dashboard, we ensure that your sheet metal parts arrive in the best quality, with a perfect fit and on time.

Contact us for a non-binding initial consultation - together we will make your sheet metal processing fit for Industry 4.0.

Newsletter Registration

Sign up now for our free Line Up newsletter and stay up to date.