Table of Contents

- How can you successfully develop your own product?

- Why develop your own product?

- Phase 1: Brainstorming and understanding market needs

- Phase 2: Concept and technical feasibility

- Phase 3: Prototyping and initial functional testing

- Phase 4: Define, ensure and document quality

- Phase 5: Certifications and legal requirements

- Phase 6: Production approval and series production

- Phase 7: Market launch and continuous optimisation

Developing your own product: 7 steps to your goal

Reading Time: 5 min.

How can you successfully develop your own product?

Developing your own product means much more than just implementing an idea. It is a conscious decision to fill a gap in the market, solve an existing problem more effectively – or drive innovation in a targeted manner. Companies that take on this challenge assume responsibility for quality, design and utility. The motivation can be varied: the desire for greater independence from suppliers, the strengthening of one's own brand or the pursuit of new business models.

But between a promising idea and a successful product lies a structured development process. This ranges from the validation of market needs to technical planning, quality control and certification, right through to the successful product launch.

In this article, we show you what a well-thought-out product development process looks like – in seven practical phases. You will gain an overview of the most important steps and learn what is important when it comes to turning ideas into marketable solutions.

Why develop your own product?

There are many reasons for developing your own product – and they are often strategically motivated. Companies that develop their own product solutions strengthen their position in the market in the long term. They become less dependent on standardised offerings, focus on unique selling points and increase their influence on quality, delivery capability and margins.

A tailor-made product can be tailored precisely to the needs of a specific target group. At the same time, innovation potential that has remained untapped in existing solutions can be exploited. The investment can also be worthwhile economically: with your own product, you not only expand your portfolio, but in the best case scenario, you create a scalable business model with long-term effects.

Last but not least, control over the entire process also plays an important role: from design and materials to packaging, you can set your own standards – and thus respond specifically to market trends, sustainability requirements or industry-specific regulations.

Whether as a starting point for new business areas or to strengthen your own brand, developing your own product is a worthwhile endeavour.

Phase 1: Brainstorming and understanding market needs

Every development begins with an idea. But not every idea automatically translates into a viable product. The first step is therefore to analyse the market: Is there a real need? What problems can you solve with your product? In this phase, it is worth taking a structured approach – using creative methods such as the SCAMPER technique or customer interviews to gain clarity about the benefits and feasibility as early as possible.

The focus is on product validation: the aim is to reflect the idea against real requirements before time and budget are invested in development.

Phase 2: Concept and technical feasibility

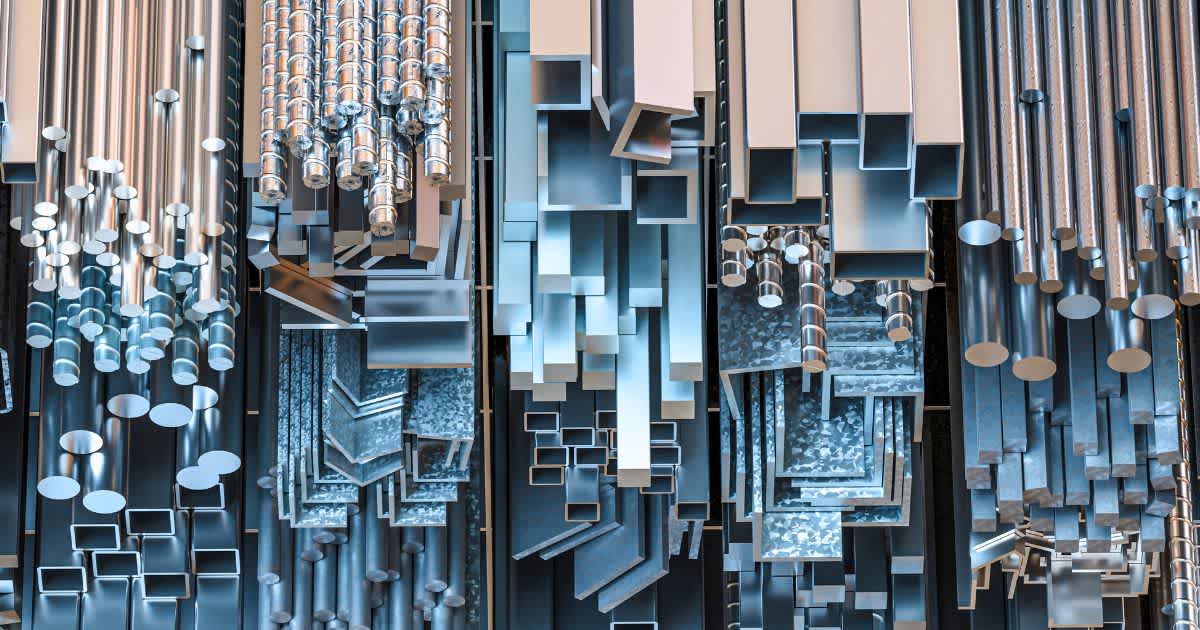

Once a product idea has been validated, the actual design process begins. This involves not only the design and function, but also materials, manufacturing options and subsequent testing requirements. An early technical feasibility analysis helps to avoid corrective loops later on.

External support can be particularly useful at this stage – for example, when evaluating manufacturing technologies or selecting suitable components. Line Up supports companies in this phase by advising them on the selection of suitable materials and manufacturing processes, among other things. With our understanding of technical feasibility and market requirements, we provide you with strategic support even before the first sampling.

Phase 3: Prototyping and initial functional testing

A prototype translates the concept into an initial physical or digital form. It serves not only as a visual model, but above all as a test object for functionality, haptics and user-friendliness. The aim is to obtain concrete feedback as early as possible – both internally and externally.

Many companies rely on iterative processes with several development stages. Simple test models allow important insights to be gained before time and resources are invested in a more complex series solution. Initial material tests and technical tests are also part of this phase of product testing.

Phase 4: Define, ensure and document quality

A successful product is convincing not only because of its concept, but above all because of its reliability. It is therefore advisable to define clear quality criteria early on in the development process. These include, for example, tolerances, technical specifications and test methods. Standards such as ISO 9001, AQL test plans or documented incoming goods inspections are not just a regulatory requirement – they create trust among customers and minimise complaints.

Our quality assurance services include individual test plans, sample approvals and test certificates in accordance with DIN EN 10204 (e.g. acceptance test certificate 3.1). This means that quality is not left to chance, but is structurally anchored – a clear competitive advantage in saturated markets.

Phase 5: Certifications and legal requirements

Depending on the type of product and target market, certain requirements must be met – whether through legal regulations or industry-specific standards. Product certification is an important part of this step and should be planned in good time.

Whether CE marking, declarations of conformity or documented test reports: the earlier regulatory requirements are incorporated into the planning, the smoother the subsequent implementation will be.

Line Up supports you in the preparation and implementation of these requirements. Through structured preliminary checks, we minimise delays in the project plan – and ensure a smooth transition to production.

Phase 6: Production approval and series production

After successful testing and certification, the transition to series production is imminent. This is where it is decided whether the developed product can also be manufactured on a larger scale in a stable, efficient and consistent manner. Series production often begins with a pilot batch or sampling to test processes and issue final approvals.

Many companies also use this step to refine communication with suppliers, document processes and implement test plans. Careful production approval minimises risks, avoids waste and ensures consistent product quality.

We support companies with production approval, coordinate sampling, analyse initial samples and assist with supplier selection, drawing on our experience from numerous projects. This is how a prototype becomes a market-ready product.

Phase 7: Market launch and continuous optimisation

The product launch is the visible culmination of the entire development process – and at the same time the beginning of a new phase. Customer feedback, initial market experiences and internal feedback provide valuable information for further optimisation of the product.

A structured feedback mechanism – combined with quality-assured testing and clear data – makes the difference between a one-off product success and long-term market penetration. We are also on hand to provide advice during this phase – analytically, proactively and solution-oriented.

Conclusion: From idea to marketable product

Developing your own product is not a spontaneous decision, but a process that requires vision, structure and discipline. Those who are prepared to consistently follow this path – from careful idea validation and well-thought-out prototyping to quality assurance and successful market launch – not only create a product, but also genuine added value.

A clearly defined product development process helps to minimise risks, use resources in a targeted manner and make fact-based decisions. This is a decisive advantage, especially in complex markets.

No one has to go it alone. External partners who structure processes, assess technical feasibility and professionally ensure quality can play a valuable role. This is how a good idea becomes a convincing result: a product that works, is well received and lasts.

Line Up accompanies this process at all levels: with sound expertise, clear quality standards and a practical perspective.

We would be happy to advise you individually on any questions you may have – click here for our contact form.

Newsletter Registration

Sign up now for our free Line Up newsletter and stay up to date.