CNC vs. injection molding - how to choose right

Reading Time: 5 min.

Choosing the right manufacturing process is a crucial step in any production project. Our guide gives you an overview, highlights the most important criteria and explains when CNC machining offers advantages and when injection molding is the better choice.

Anyone who has components developed and manufactured is often faced with the question: should the parts be produced using CNC (Computerized Numerical Control) machining or is injection moulding worthwhile? And even though both have proven themselves in industrial practice, they differ significantly in terms of cost, material usage, speed and scaling.

CNC machining and injection molding in comparison

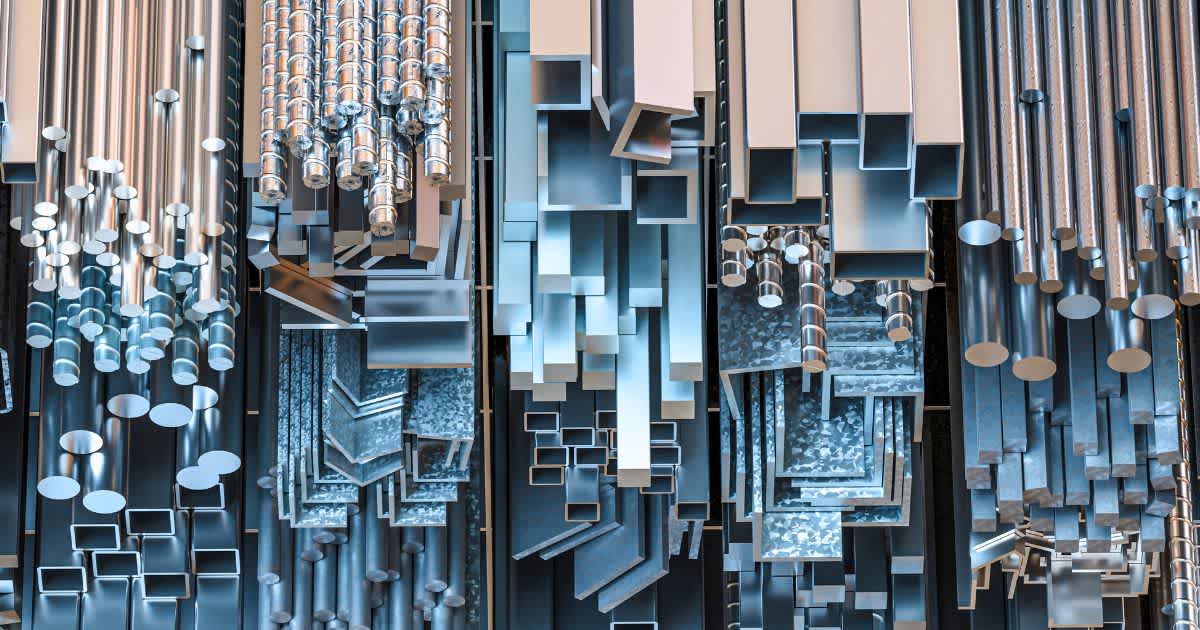

CNC machining and plastic injection molding are among the most frequently used processes in modern manufacturing. Both methods use different approaches to produce components with high precision and quality.

For CNC machining:

A workpiece is machined out of a solid block of material.

Milling and turning machines remove material layer by layer until the desired geometry is created.

The method is suitable for metals such as aluminum or steel as well as engineering plastics.

It scores particularly well for individual parts, small batches or complex geometries that require a high degree of dimensional accuracy.

For injection molding:

A primary molding process is used.

The granulate is melted and injected under high pressure into a mold in which it solidifies.

The process is particularly attractive when larger quantities are required, as components can be produced quickly and with high repeat accuracy after the cost-intensive production of the mold.

Typical applications range from housings and technical components to consumer goods.

While CNC machining impresses with its flexibility and low start-up costs, injection molding shows its strengths with high quantities and consistent geometry.

5 criteria that are decisive for the choice

1. component geometry

CNC machining is particularly powerful when complex geometries with undercuts, precise drill holes or variable wall thicknesses are required. This is because CNC machines can convert contours directly from CAD data and adapt them flexibly.

Injection molding, on the other hand, requires a form that can be demolded. Extreme undercuts or very delicate structures are only possible with complex tool mechanisms. However, if the component is designed in such a way that it is suitable for injection molding, even complex surfaces and structures can be reproduced with high repeat accuracy.

Conclusion: CNC is the better choice for prototypes with variable geometry or components that are still being adapted during the development process. Injection moulding offers advantages for series with optimized shaping.

2. batch size and production quantity

CNC machining scores highly for small batches and individual CNC parts. This is because the machines can start without special forming tools, which keeps start-up costs low. Changes can be implemented quickly without the need to manufacture a new tool.

Plastic injection molding only reveals its potential with larger quantities. Although the tool costs are high, the unit costs fall significantly with each unit produced. Injection molding usually becomes more economical than CNC when several thousand parts are produced.

Conclusion: CNC is worthwhile for initial product series or limited orders; for planned series production with high quantities, there is no way around injection molding.

3. material variety and material properties

Aluminum, stainless steel, brass or technical plastics can be precisely machined via CNC. This makes it possible to use exactly the material that provides the desired properties, such as high strength or special surfaces.

Injection molding, on the other hand, is limited to thermoplastics. These offer a wide range of possibilities in terms of color, fillers or additives, but are dependent on processability in the injection molding process. For components with requirements for transparency, flexibility or impact resistance, there are proven standard types in the plastics sector.

Conclusion: If metallic materials or special materials are required, CNC machining is the way to go. For components that can be produced in plastic, injection moulding opens up a wide range of material options.

4. cost structure

There are no tool costs for CNC parts, but the processing time per part is higher. Each contour is milled or drilled individually, which keeps the cost per part constant - regardless of whether you want to produce just ten or a thousand parts.

Injection molding initially requires an often expensive tool, but once it has been produced, the production costs per part are very low. The costs therefore fall with increasing quantities. The investment in the tool is amortized when a sufficiently high batch size is achieved.

Conclusion: CNC impresses with low start-up costs and costing reliability for small quantities. Injection molding is the economical solution for large quantities.

5. speed and time-to-market

The first sample parts can be available for CNC machining just a few days after approval and changes can also be implemented at short notice. This flexibility makes CNC ideal for prototypes or test series.

The development and production of an injection mold, on the other hand, can take several weeks. After that, however, components can be produced in large quantities in a very short time.

Conclusion: If you need initial parts quickly or expect changes, CNC has an advantage. For long-term series production with consistent geometry, injection molding offers the higher speed per part.

Trends and hybrid strategies in modern manufacturing

In order to get the best of all worlds, the boundaries in industrial production are becoming increasingly blurred. Today, various processes are used, supplemented or combined in order to shorten development times, reduce costs and respond flexibly to market requirements.

Hybrid strategies in practice

A frequently used approach is the combination of CNC machining and injection molding within a project: in the early development phase, companies initially produce prototypes or functional samples using CNC machining.

This allows component geometries to be tested, material properties to be checked and design changes to be implemented without a great deal of effort. Only once the component has been validated and all adjustments have been completed do manufacturers invest in an injection mold and start series production. This minimizes the risk of expensive tool changes.

Rapid prototyping as an addition

In addition to CNC and injection molding, additive manufacturing is also establishing itself as the third element in the process chain. 3D printing processes deliver sample parts within a few hours, which can be used to make early design decisions. The findings from this are in turn incorporated into CNC samples or the design of injection molding tools.

Trend towards agile production strategies

More and more companies are relying on agile production chains. This means small batch sizes and flexible production methods at the beginning in order to optimize design and specifications iteratively. And only once the product has been validated on the market is it transferred to highly automated series production using injection molding. This strategy saves resources and reduces the risk of undesirable developments.

Digitization and simulation

Digital twins and simulations support these hybrid strategies. This is because it is possible to simulate how a component will behave in real use even before the first milling or spraying. This allows optimizations to be brought forward and the choice of the right process to be made on a sound basis.

CNC or injection molding: make the right decision

As you can see: The decision between CNC machining and injection molding depends heavily on the requirements of your project. CNC is convincing if you need prototypes, individual items or small series. Changes can be implemented quickly and you benefit from a wide range of materials and short throughput times.

Injection molding, on the other hand, comes into its own when large quantities are required and the geometry is fixed. After investing in a tool, components are produced in a short time and with consistently high quality, which is ideal for series production and long-term projects.

This means that if you clearly define your requirements, you can reduce time, costs and risks by making the right choice. Line Up supports you with many years of experience, a strong international network and solutions that fit your product and your schedule exactly. Simply contact us using our contact form.

Newsletter Registration

Sign up now for our free Line Up newsletter and stay up to date.